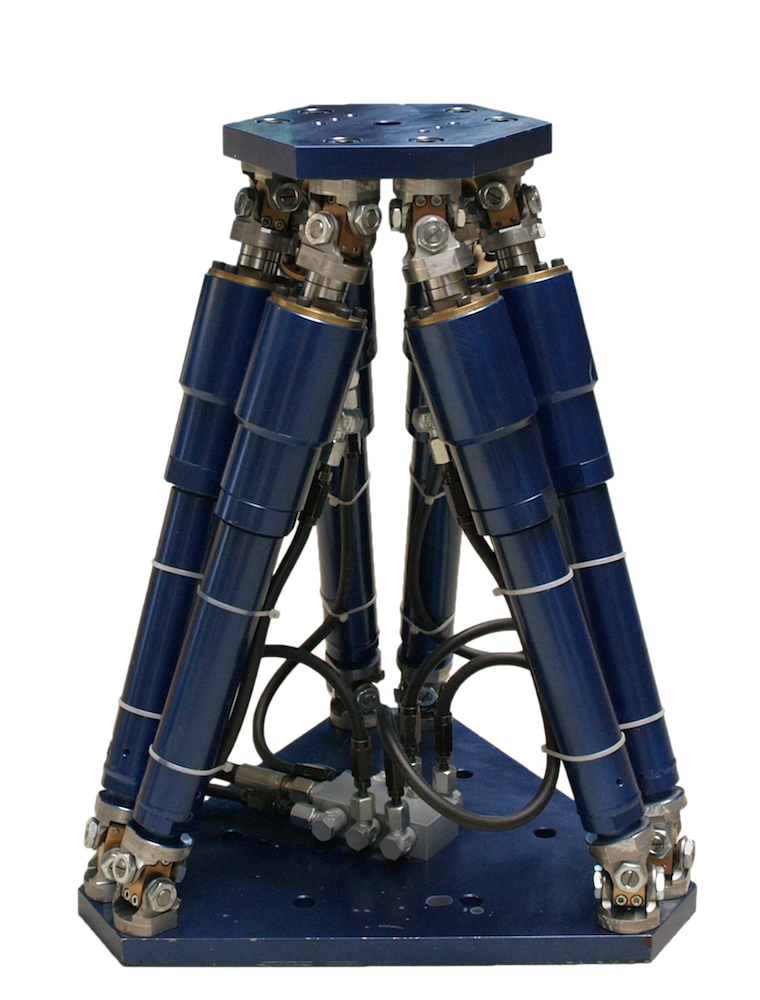

Avg.stiffness

1300 N/mm

The Hexapod system from Flex Hex can be utilized in any industry where fixed fixtures are used in production. If you want to improve the production quality, save time expenditure on changeover reconfiguration and calibration between production batches, improve working environment and keep costs down without changing the existing environment, then this is the cheap but accurate solution for you.

The Hexapod System is ideal for industries where assembly processes are a big part of production, like semiconductory, plastic, rubber, metal, automotive, railways, airplane industries. Also System Developers and Integrators who seek to offer clients an innovative method of improving the flexibility of their production.

The Hexapod system is fully integratable with other robot activities in production lines. The merging of these two technologies lead to an economical feasible, flexible and high quality fixture that ensures higher stiffness and accuracy in fixating workpieces in e.g. a production line.

1300 N/mm

500 kg

0.01 mm

0.08 mm

hydraulic pressure clamping system

width: 392 mm

depth: 345 mm

high: 488-674 mm

delivered with a pressure intensifier to active/deactivate the clamping

The Hexapod system is ideal if you want to optimise the time used in changeover between batches and decrease downtime of production

Due to the patented joint system, the Heaxpod system after positioning by the robot arm keeps a very accurate position with any deformation compared to a fixed fixture, even in extreme position.

The hexapod system consist of several Hexapods, the number will depend on the fixture configuration of the site of manufacturing, the required production setup and weight requirements. A Hexapod is a robot fixture which can be featured with passive reconfigurable and adaptive tooling on the base plate. It can be reconfigured automatically by a robot arm.